- Home

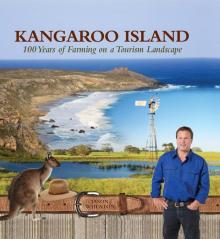

- Jason Wheaton

Kangaroo Island Page 5

Kangaroo Island Read online

Page 5

The mouldboard plough was used after the initial rain to turn the soil prior to seeding. As seen in this picture the machine is not very wide and this process of ploughing land took some time however, this was the most efficient process in the late 1930s.

The introduction of the Sunshine harvester was a revolution in its time and in a way changed the method of harvesting grain forever.

This method of harvesting was very time consuming, compared to the methods of today. The efficiency with which grain is harvested today and the method of getting the grain to ports for both domestic and also international trade is profound.

The Sunshine harvester was produced by H.V. McKay in Victoria in the 1920s. At the age of 18 Hugh Victor McKay developed the Sunshine harvester to create more efficiency in agriculture. HV McKay also invented the mouldboard plough which was used extensively at Stranraer for cultivation prior to crop production. This machinery technology improved productivity for agriculture on Kangaroo Island and around Australia and revolutionised farming.

The Sunshine harvester operated through the 1930s, 1940s and the 1950s before the Massey Fergusson 585 harvester was introduced. The Massey 585 header was a ground-breaking piece of machinery for its time; it brought greater efficiency into harvesting crops in Australia. Our Massey 585 is parked up and home to a few possums near the hummocks, however it reminds us of the many hectares that were harvested with this machine.

The use of two sunshine headers certainly made the process of harvesting quicker with the use of the international tractor.

There are many Sunshine harvesters parked up on farms, all of which can tell a story of a bygone era.

The grain was harvested into the main hopper on the Sunshine harvester. Once the harvester was full of grain it would stop and be bagged off with a side chute. The harvester once unloaded would continue until full again. In most cases there were 2 bagging points in the paddocks to allow the unloading of the grain into the bags. By having two stations this would allow for centralised pick up of the bags. A truck would pull up to the bagging areas and elevate the bags onto the truck via a chain operated elevator.

The Sunshine harvester had a record of bagging off 400 bags of grain in one day. These bags weighed 190 pounds. That equates to an 85kg bag of grain. Now that is hard work!

34 tonnes of grain moved in one day, in 85kg bags. As can be seen in the picture above, the Sunshine harvester had steel wheels which made it a heavy machine to pull.

The Massey Fergusson harvester operated in a similar way. The most grain harvested in one day was 600 bags.

Harvesting machinery in the 21st century provides farmers with the ability to cover larger areas more efficiently.

Harvesters have become self-propelled as opposed to the powered take off, shaft driven headers such as the Massey Fergusson 585.

Machinery for seeding in the modern era as seen above is concentrated on minimal soil disturbance and maximum seed and soil contact. This reduces the impact of soil compaction and allows for more even consistent germination of the crop.

The progression of machinery over the past 100 years has been very dramatic. Tractors were fitted with cabins in the 1970s and 80s for safety. The management of grain has also advanced with the design of the chaser bin which can follow the header in the paddock and allows the grain to be loaded from the header to the chaser bin whilst the header is still harvesting. Now that is time management!

CHAPTER 4 - Stranraer ‘Safe Port’

Land management in the early days required a burning process and this allowed the management of the thick scrub and regeneration of the pasture. At this point of land clearance in the 1920s and 1930s, there were no big tractors or heavy ploughs, so scrub regrowth was a problem. The advantage of burning was the soft regrowth that the sheep would graze after a ‘soft burn.’ These soft burns were done in late winter (July, August) when conditions were beginning to dry but temperatures were still low. Now, with approximately one third of Kangaroo Island proclaimed a national park, fire management is very important. ‘Cold burns’ are operated by the National Parks to manage the fuel loads. Bullocks were used in the early days to clear the scrub especially around Kingscote, however these were superseded by the Clydesdale horse due to their efficiency.

In these early years agriculture was the main source of income, wool, barley, fruit and vegetables were the main staples of the time. Fishing was a developing industry. The yacca industry, especially in the western part of Kangaroo Island, employed large teams of men.

The council’s focus in the early years was to protect agricultural industry from pests such as rabbits and foxes and this has provided Kangaroo Island with a relatively pest free environment in which to raise livestock. There are no rabbits or foxes on Kangaroo Island today due to their commitment. There were also bounties offered to farmers who collected scalps, heads and eggs of crows and sparrows but this was discontinued in the early 1900s as the council saw it was a battle that could not be won. The crow is still a pest, especially with young lambs and ewes. Over the years I have seen numerous crows swoop into the chook house and steal eggs from right under their noses. I remember watching my brother a few years ago, who could hit a golf ball pretty well, hit a ball down the paddock. The ball went about 200 metres and we were standing there admiring the shot. The next thing a crow swoops in and steals the golf ball, thinking it was an egg. So the crow can even stuff up a casual round of golf.

Bounties were also offered on the pink galah which was causing major issues with grain producers. Pink Galah’s would dig up the seed after planting and also eat the young emerging crop. This bounty did not last long due to the sheer number of birds. Pink galah’s’ are still prevalent in large number at Stranraer today.

Transport to the island was a major issue, especially with the movement of agriculturally related products such as wool and sheep. The Kingscote jetty was opened in 1910. The S.S. Karatta was the first vessel to be used between Adelaide and Kangaroo Island. The Karrata was a coal burning ship, which was later converted to oil. This vessel was used for 50 years to provide a service to the island. The M.V. Troubridge then operated from the early 60s. For the calendar year of 1962, 11,322 passengers and 1,988 cars were carried by sea, while aircraft accounted for 15,616. Sheep, cattle and pigs were also transported to Adelaide on the Troubridge. This same year 114,638 sheep, 3,812 cattle and 2,264 pigs were transported from Kangaroo Island. Stranraer was involved in the production of all these categories. Pigs were transported to the wharf in Kingscote via a truck with a stock crate on the back.

The Troubridge was primarily a freight carrying vessel and farmers were concerned about the number of people and cars being transported at the detriment of livestock. Farmers had to book in livestock to be transported ahead of time and farmers groups were encouraging the council at the time to give priority to livestock over passengers. This situation changed in 1985 when the Philanderer was built as a passenger vessel to operate between Cape Jervis and Penneshaw. This service was to develop into the current Kangaroo Island Sealink Service for both passengers and freight.

All livestock from Stranraer is placed onto semi-trailers and trucked to Adelaide. The trip from Penneshaw to Cape Jervis takes 50 minutes followed by a 2 hour trip to Adelaide. Wool is transported the same way. Most livestock, mainly cattle and sheep are moved to and from the island from August until January in any given year.

The Sealink operates between Cape Jervis and Penneshaw and travels the 16km journey 2-3 times a day and more in the peak holiday season.

The Parndana, which was used at the time of the Karrata, was also an effective boat in transporting goods to Kangaroo Island however, the maximum lift possible via small crane with this boat was 3 tonnes; the Karatta could lift 5 tonnes from the boat to the jetty. For this reason this boat was the preferred option in most of the freight transfers.

Stranraer by definition is a reflection of the town Stranraer in Scotland meaning ‘safe resting place’ or ‘safe p

ort.’

Stranraer today is comprised of 3200 acres or 1295 hectares in the new language and divided into 40 paddocks.

Stranraer has been in the Wheaton family for over 100 years. The property has been run primarily as a sheep property, however cereal production has also occurred, which includes wheat, barley and oats while canola, triticale and faba beans have also been grown on the property.

Pasture plants such as sub clover, lucerne, chicory and perennial grasses such as phalaris and ryegrass have been dominant over the generations to support the various livestock industries.

The carrying capacity of the property is approx. 3500 breeding ewes with the main focus for current agricultural production being prime lamb and wool production, operating in a rainfall zone of 450 millimetres or 18 inches. 80-100 bales of wool are cut and 2500-3000 lambs are sold annually. The property is home to the White Lagoon Wetland System comprised of Rush Lagoon (141 hectares) and White Lagoon (255 hectares).

Stranraer international and domestic tourism has been operational since 1996. Stranraer is located 25km south of the nearest town of Kingscote, and 15km south of the local airport. D’Estrees Bay, a popular local fishing and swimming bay, is 10km from Stranraer and is home of the King George Whiting, a popular South Australian fish served at Stranraer.

The homestead has numerous fireplaces and the requirement for wood supply especially during the cold winter months of June, July and August was constant. The chopping of wood years ago was with an axe and then it progressed to the circular saw that was run via the power take off shaft on the back of the tractor. Maintaining the fireplaces for guests is still a big job but with the installation of slow combustion fireplaces the demand is not a high as in the early 1900s. Eucalyptus cneorifolia (Kangaroo Island Mallee) was commonly used for the fireplaces as it is today.

The old clothing mangle was used to remove water from clothing prior to going on the clothes line and remains on the verandah as a reminder of the house processes of yesteryear.

With no refrigeration in the early days, Stranraer operated a cellar which was located at the southern edge of the verandah, near the kitchen and would allow for food and beverage storage. The cellar was a step down cellar and stored food and drink at low temperatures. The photo below shows the iron roof of the cellar in the foreground.

Stranraer construction was completed in two halves with the northern half completed first. The original three bedroom house was removed on the southern end to make way for the southern section. The family lived in the northern area of the house until completion.

The architectural plans for the homestead construction were completed in 1919 and the construction was completed in 1926. Prior to the construction of Stranraer, Adavale (which was the original name of the property) comprised of a three bedroom home. This home was on the site where Stranraer exists today. The northern half of Stranraer was constructed first, then the three bedroom home was removed while the family lived in the newly constructed half and the remaining southern half of the house was completed. The house was completed in two halves over a five year period. Two old mulberry trees were removed from the site of the northern half prior to construction and the trees were towed down to the edge of MacGillivray oval, where they continue to bear fruit today.

Pig production was part of many farms on Kangaroo Island in the early days. Grain production on the property supported the growing of pigs for local consumption as well as providing extra income through the sale of pork into Adelaide.

The Stranraer shearing shed was constructed in 1936, made from limestone located in nearby paddocks. This construction took over 12 months. The completion of the shearing shed and yards coincided well with regards to the development of the property; as the land improvements and clearing was occurring the more sheep could be run on the property and the facility was used immediately.

The shearing shed could house up to 300-400 sheep to allow shearing to occur. It is important to keep the sheep dry prior to shearing to enable the wool to be place in wool packs and for shearer comfort.

The building of the shearing shed commenced in 1935 and was completed in 1936.

This stud was used to produce rams to be crossed with the merino ewe to create a dam for prime lamb production, known as the crossbred ewe.

The infrastructure of the property allowed for management of the livestock in the early days as it does today.

CHAPTER 5 - Farm Management At Stranraer

The water used domestically at Stranraer is rainwater. There is no main water supply brought to this region of Kangaroo Island, thus there is a reliance on rainwater. All shedding has rain water tanks which is channelled back through to the homestead. In recent times, tanks have been placed on the new implement shed, grain shed, shearing shed and cottage. Local town water, Kingscote, is supplied by Middle River Dam on the western end of the island.

In the early days water was pumped to an overhead tank that would create the pressure to supply the house. This tank stand remained for many years and was used right up until 2007. The overhead stand was supported by 4 concrete pillars and was located south of the homestead. Water is now pumped to the main house via electric pump but in times of power failure a petrol powered generator is used.

The original rainwater tank was built into the ground on the eastern side of the homestead and still exists today.

Stranraer has ground water that has enabled the construction of windmills in the past to allow this water to be moved around the farm. Water is moved in 2.5” poly pipe from north to south. Windmills were constructed in the 30 acre paddock along with Rush Lagoon where 2 windmills were placed. Vietch’s also had a windmill making 4 windmills in total. The quality of water in each region changes with salt content. The windmills were crucial in setting up the property in the early 1900s. Water movement today does not rely on windmills. The use of centrifugal pumps has replaced the need for high maintenance windmills. Water was originally sourced on the edge of Rush Lagoon however, when the lagoon filled up the bore would fill with silt. To counteract this problem a four foot cement pipe was placed on its end in the hole. This still remains on the edge of Rush lagoon today.

Pipe was laid to the shearing shed to store this water for livestock. The original pipe system was galvanised links of pipe screwed together with threaded sections. The laying of the original galvanised pipe took place in 1912 by Robert. The pressure for the water transfer was carried out by windmills as seen in the above picture.

Water was also pumped from Wattle Grove in this way to storage tanks on the hill opposite the stables and continues in a southerly direction to another 1000 gallon tank that still exists today.

In the early 1960s very dry conditions existed causing issues with watering stock for most farmers in the district. The bore located on the eastern edge of Rush Lagoon assisted farmers in the area by allowing access with water trucks. 10-12 local farmers would source water from this bore during this period of very dry conditions. Trucks could only hold 300-400 gallons at a time, meaning that this job would seem never ending over the summer period. Local farmers would then return to their properties and unload the water into holding dams. The bore on the eastern side of Rush Lagoon is 3000ppm salt. This is Stranraer’s best quality water. In the tough year of 2006 this bore supplied water for more than 6 months. A centrifugal pump was started every day during this period. In 2006 due to the concern of lack of water and the dry period another bore was put down in the hill paddock. This water is not the best quality, at 8000ppm, however it assisted during this period. This bore is cased and functional today.

Dams are present at the northern and southern ends of the property. Due to the topography, runoff water is limited but the clay base of these dams at each end of the property provides a good water supply and reduced reliance on piped water during the summer months.

The laying of the inch and a half diameter pipe to move water around the property to supply trough water for the livestock. As the wheels turned the pip

e would feed into the ground, which had already been ripped. There would be more than 30km of pipes to move water around the property today.

Prior to the use of poly pipe or plastic pipe, metal pipe was used. With the salinity levels in some of the water, over time these pipes began to corrode. The new poly pipe of today is flexible, non-corrosive and easy to install compared to the lengths of pipe used previously and it is also not as heavy. The pipe water is plumbed into troughs for livestock. Every paddock on the property has a trough for livestock watering, which is critical for the summer period.

Water used by sheep can range from 4-10 litres per day depending on the time of year.

Sheep numbers on Kangaroo Island back in the 70s, 80s and early 90s exceeded one million. With changes to the industry such as the Flock Reduction Scheme, closure of the local abattoir and poor wool and meat prices meant many farmers exited the industry. Forestry has also had an impact on sheep numbers due to the loss of productive land. Most of the blue gum plantations occurred on the western end of Kangaroo Island through the late 90s and early 2000s. Sheep on Kangaroo Island today would be well below one million.

Kangaroo Island

Kangaroo Island